NEW MOULDS

It’s Time to Start Your New Production

Research & Development

We approach customers demands with a solution perspective of our experienced R&D staff. Before examining the products in terms of mold, we offer the most appropriate and high quality solution by examining market research, user problems, improvements and reverse engineering. We design products with the help of advanced technology software such as Solidworks and Unigraphix. At the same time, we have open and innovative perspective by internalizing the knowledge and experiences obtained from each project within R&D. We also carry out joint projects with universities in order to further our experience, knowledge and skills.

WHY US?

We bear the responsibility of being an accurate, honest, reliable and innovative organization. We are closely following the all the technologies and innovations related to our sector in mould manufacturing, plastic injection mould design, aluminum mould design and production. We constantly ensure the competence of our human and logistics resources and work with our customers in a solution partnership awareness.

Analysis

We produce constructive, high quality and fast solutions to our customers by making the necessary analyzes before starting the production of the products with the help of CAD / CAE programs and experienced staff that it uses within its R&D. Because of ANSYS program, we can perform analysis such as Static, Dynamic, Deformation, Stress, Drop-Crash test in plastic parts. Thanks to these analyzes, the most suitable and ideal product delivery is prepared to the customers by minimizing the problems that can be predicted before the production of plastic parts. We take fast steps towards becoming an R&D company by leaving a standard mould manufacturer with the competence of the ANSYS program. At the same time, we can decide the most suitable mould and injection parameters by making filling analysis of plastic parts. R&D department experience in metal injection parts and accumulated know how can make suitable runner and air-duct designs.

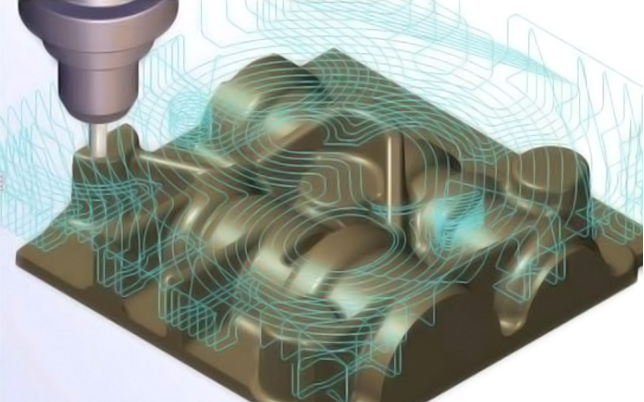

Design

The design stage is the most important of all stages. The wrong decisions to be made at this stage can cause high costs in the long term. Our R&D’s experienced team in the automotive and medical sectors will help you make the most accurate design decisions.

Simulation

With the latest technology mould simulation software, we first test the operation of the molds of your designs in the computer environment and we take precautions by predicting the errors that may occur. This way, we achieve success in the first edition and offer quality solutions economically.

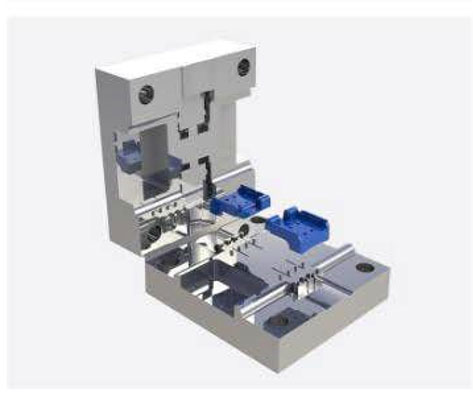

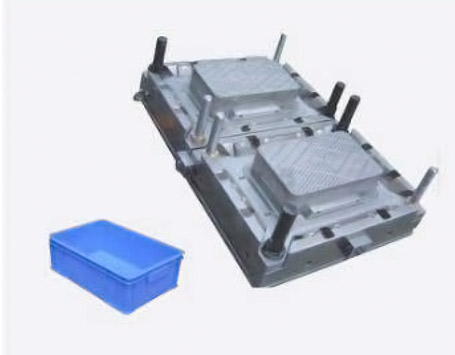

Mould design and production

One of the most critical investments in the realization of a product is mould investment. However, you can reach the desired result by working with the right team during the mould design and production phase. You should choose a reliable team so that your mould does not turn into a dead investment.

Produce and injection pressure

It is important to be able to solve your mold production and injection needs at a single point so that your molds can be tested quickly and your needs can be changed in time. Gama R&D offers you unmatched flexibility

Assembly

The assembly and packaging of your produced parts during or after injection can speed up the time to market the product, reduce error rates and positively affect your overall costs. How can we help you with our assembly team that increases and decreases according to project needs?

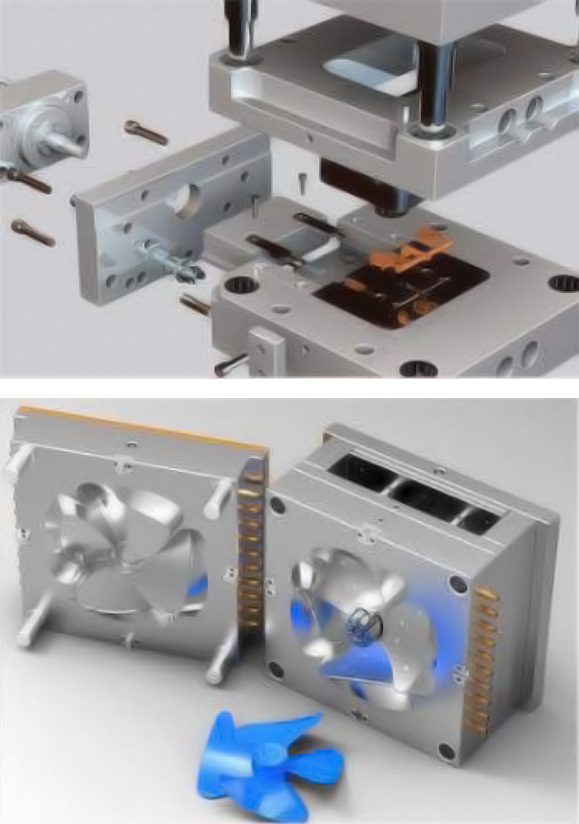

The manufacturing method performed by melting plastic raw material at high temperature and injecting it into a mould is called plastic injection. Plastic injection production method is widely used in industrial areas.

Many apart from the smallest part in life to the largest are manufactured using plastic injection method

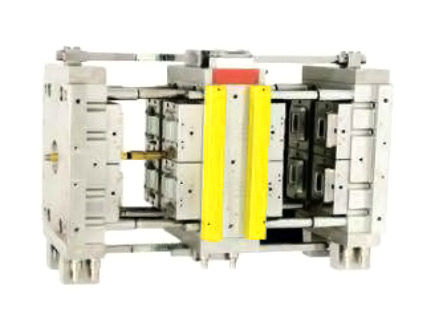

Plastic injection has been carried out in plastic injection machines since the early 1900’s. Today, these machines are production using the latest technologies integrated with systems performs. Injection molding machines generally consist of clamps, injection section and mold section.

The vice section is where the molten plastic raw material is compressed under pressure. This part is also the part that realizes the male-female harmony, which is considered as the two parts of the mold. The injection phase takes place in the relevant part of the machine. It is located in the chamber in the granular plastic raw material injection unit. The raw material, which is brought to high temperature with electric heaters, is melted and pushed into the mold section in the vise part. This pushing process continues as the injection process when the raw material is melted enough to fill the mold and the mold is filled. After the plastic material is injected into the mold and the mold is completely filled, it tries to escape from the entry point in the mold in the second phase. In order to prevent this movement, holding pressure is applied after the injection pressure the application time of the holding pressure may vary depending on the nature of the raw material used, part sizes and weight.

The process of hardening of the molten raw material in the mold, which is completely filled and stabilized by holding pressure, is carried out by cooling. After cooling, which is the last stage of plastic injection application, the product can be put into use by taking it out of the mold.

Generally, the manufacturers take care to deliver the requested product flawlessly and flawlessly by applying operations such as deburring and correction on the ready-made product. Plastic injection applications are used in an increasing technological infrastructure and allow different processes.

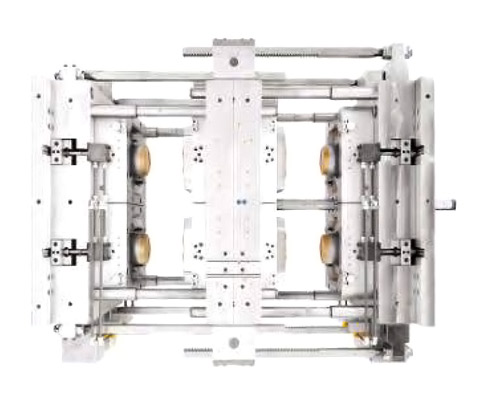

Ensuring a balanced filling in multi cavity molds is one of the basic requirements. It provides advantages such as a balanced filling, faster cycle times and more stable part quality. Filling of die cells at the same time means that all eyes are exposed to the same pressure and shear forces. The difference in size and quality between the chambers with the same polymer structure, temperature and pressure is minimized.

MAIN FACTORS AFFECTING THE FILLING BALANCE OF THE MOLD

Runner design:

Eyes with different flow lengths fill at different times. Runner design can be naturally balanced and artificially balanced. The flow length is equal in naturally balanced runners. On the other hand, artificially balanced runners are balanced by applying different wall thicknesses in different lengths of flow paths.

Slip velocity:

High sliding velocities at runner edges It causes the formation of different temperature areas on the plastic. Because the warmer plastic moves faster, the inner mold chambers fill up faster.

Mould:

Gas channels, runner inlets, cavity, cooling channels, hot runners and imbalances on the mold like these can also be filled. It affects the balance to a significant extent.

Our metal injection facility was established in 2005 with the experienced team of mould and machinery and equipment covering the latest innovations in aluminum casting technology. Unit cost advantage is provided to existing white goods and automotive industry customers with mold manufacturing and processing support. In our facility, cold chamber, high with pressurized metal injection presses, aluminum parts are produced for the automotive, white goods and aviation sectors.